Astrid Wynne, Techbuyer Sustainability Lead and Chair of the Sustainability SIG at the Data Centre Alliance, explores in depth David Gyulnazaryan’s recent discussion about the practicalities of reducing carbon with effective heat management and why Techbuyer is particularly interested in how this can be applied to heat and energy as well as the IT hardware and associated materials.

The first law of thermodynamics, also known as the law of conservation of energy, states that energy can neither be created nor destroyed, but changes from one form to another. The electrical energy that data centres draw through the servers is almost entirely converted to heat. Data generation is a biproduct of this, but accounts for less than 0.1% of the conversion, which means that the term ‘data centre’ is a misnomer in energy terms. It is more accurate to call them ‘heat centres’ which can also be used to process and store information. Flipping thinking in this way allows us to be more creative about how we plan and manage data centre builds now and – much more importantly – in the future.

David Gyulnazaryan is somewhat of an evangelist for Combined Heat Compute and decarbonisation. His recent talk at Data Centre World London attracted a crowd of 200 people to a side theatre, who were interested in the practicalities of reducing carbon with effective heat management. As an organisation that is committed to the Circular Economy, Techbuyer has been interested in how this can be applied to heat and energy as well as the IT hardware and associated materials. It has been interesting to discuss this with Gyulnazaryan.

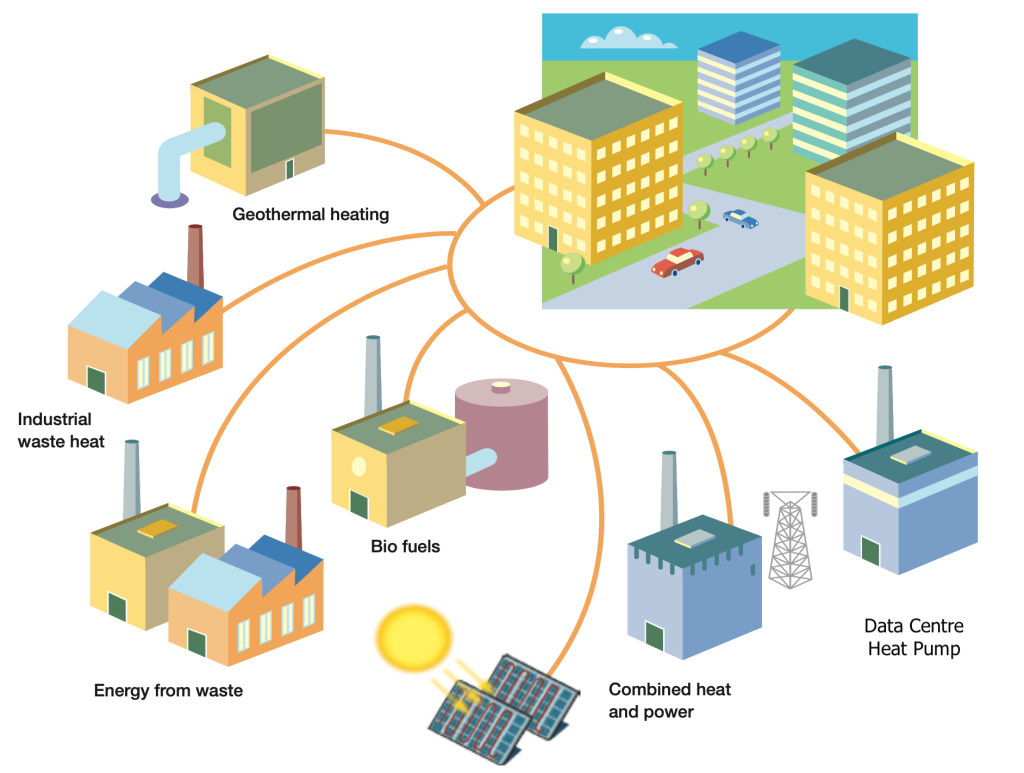

One of Gyulnazaryan’s initial points is that the shift in thinking requires a holistic view of heat generation at district level, in which data centres are one moving part. Low grade heat is supplemented by heat from other industrial sources such as biofuels, geothermal heading, energy from waste and others, as shown below. It is a systems-based approach that is best integrated into town planning. With the data centre sector expected to grow by 500% globally by 2050, this is not such a stretch for the future as it may appear today.

The concept of heat reuse is not a new one. Lefdal Mine Datacenter in Norway runs a cooling system using 9°C water from a fjord through the cooling system and delivers 20°C water to a nearby salmon farm. Green Mountain operates a similar system in Norway to feed a trout farm. EcoDataCenter operating in Sweden is designed to pump heat into the local town of Falun for district heating and also to feed the pellet manufacturing site in the area. These early examples lead some to believe that the solution only works in cold climates. However, Gyulnazaryan is keen to point out that that is not the case.

Global application

A lot of food production requires heat to prepare and to package. Beer, milk products and pharma manufacturing also use the heat, as do the production of plastic and rubber, desalination projects, warming water for washing machines, showers etc. Each of these processes already uses warm water, which is currently produced with electric systems or boilers. Integrating data centres into the process means doubling up on use of heat and reducing our reliance on heat generation from other sources. This means there are opportunities to apply the concept to warmer climates and in areas of seasonal fluctuation. When the weather gets warmer, for example, the energy can be diverted from warming houses to fermentation sites.

Circular design

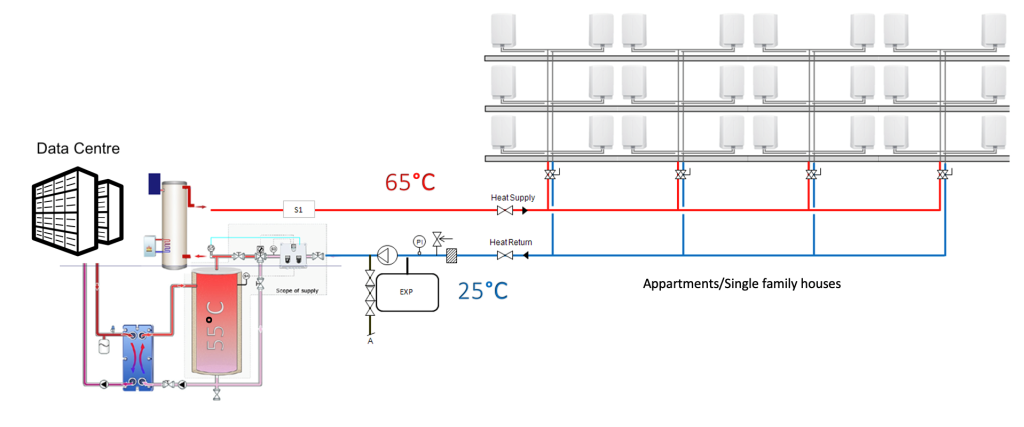

Gyulnazaryan says there is scope to introduce a circular system between the data centre and external systems, as he explains with this example from district heating:

“When we use a heat pump, or chiller for data centre heat transfer, we add 25-30% to the IT-equipment heat rejection. In district heating, the heat losses are around 10% through the pipes due to high grade temperature of water and the large difference with the ground temperature. However, if we choose instead to feed systems like underfloor heating, it means that the heat loss is absorbed into heating the house. What’s more, the heat loss that goes on in the district heating is useful for the data centre because it eventually lowers the temperature to 20°C, which can then be fed back into data centre cooling.”

Retrofit

“Usually, data centres are equipped with chillers and dry coolers, which reject the heat into the ambient air, where it is difficult to harvest,” said Gyulnazaryan. “As an alternative to using dry coolers, we can connect chillers to the heated pipes, which provides water heated to 50-60°C. If we need to increase temperature, then we can use second stage heat pumps. These types of systems can be installed inside the data centre building or outside in modular containerised solutions. This system can be used instead of a fuel-based boiler at the recipient’s end and eliminate their use of carbon. The process can be reworked if the recipient is using integrated electrical heaters, but we need to rethink the process line.”

Getting buy-in

There has traditionally been a lot of discussion in the sector on the difference between the ‘handprint’ of data centres (i.e. the positive effect data storage and transfer has on carbon emissions) vs their ‘footprint’ (or the GHG emissions they are responsible for). The concept of heat reuse highlights a further extension of the handprint. As Gyulnazaryan explains:

“There is a huge opportunity here for district heating companies to receive a highly sustainable and reliable source of heat from data centres. This comes with a high content of renewable energy use and is backed up by power generation in case of failure, which gives a 99.996% level of reliability. On the financial side, the cost of converting low-grade heat from the data centre is approximately €25/MWh, whereas the natural gas price is around €200/MWh. The monetary saving potential is huge for public bodies, particularly when natural gas supply is reducing.”

These benefits are a huge encouragement to local governments and town planners who want to ensure supply in a difficult market. Price rises caused by global events, an imperative to reduce reliance on hydrocarbons and logistical challenges around transitioning to a renewable grid are all reasons why decision-makers should be interested in this. Many districts and governments are announcing Net Zero and Circular Economy plans as a matter of urgency. The sector would do well to signal heat reuse as part of a toolbox to deliver on this. Achieving the carbon reductions necessary by 2050 means a whole systems approach. Integrating data centres into this would go a long way towards achieving success.